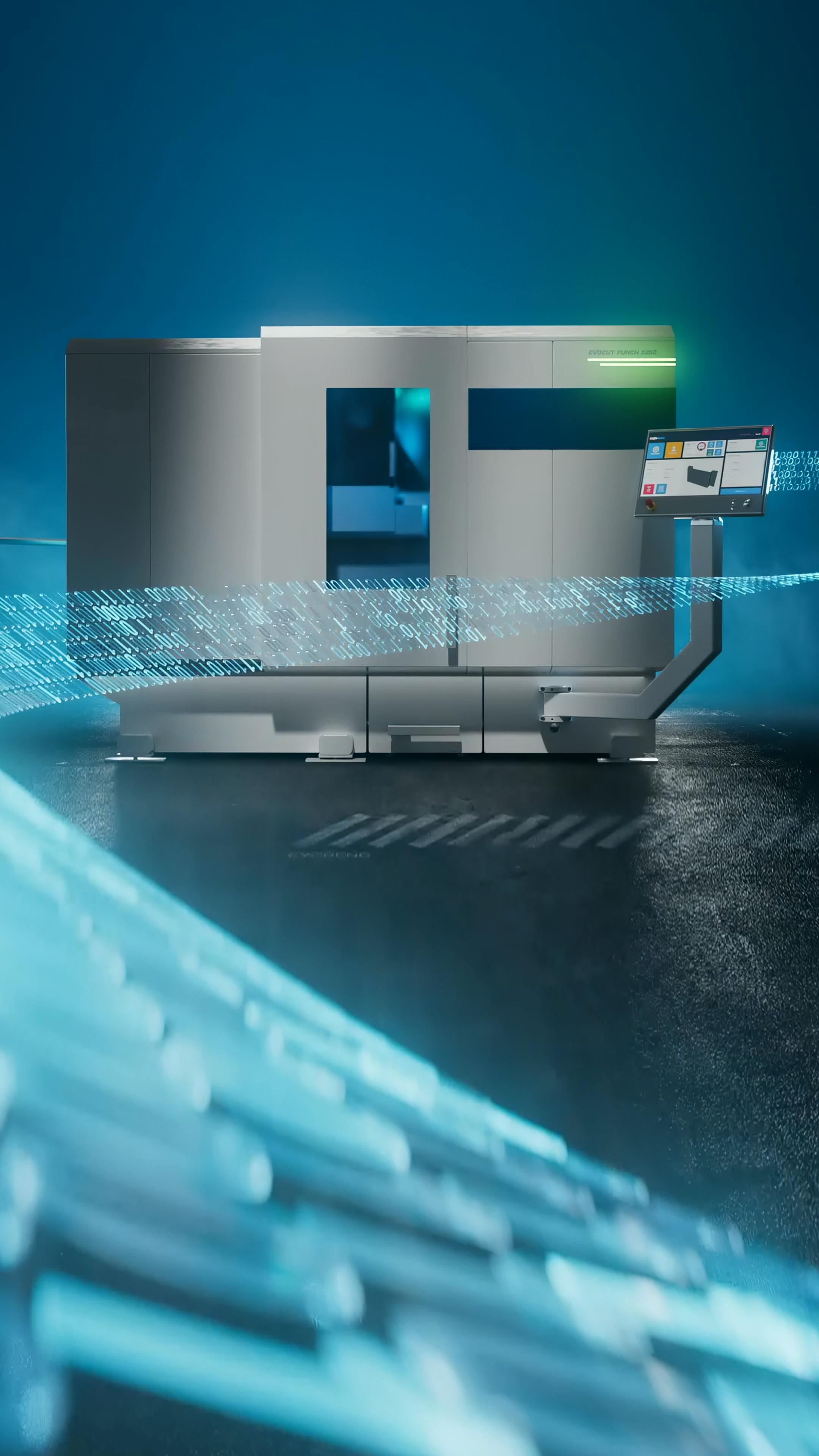

Our machines set new standards in sheet metal processing. With industry-leading technology, 100% electric drive, and decades of experience, we deliver unmatched speed, precision, and safety. All EVOBEND machines are designed for maximum performance and usability – delivering the best results the market has to offer. EVOBEND represents quality that stands out and innovation that drives progress.

EVOBEND not only sets new standards in functionality but also stands out with its exceptional energy efficiency. With up to 90% energy savings, it delivers superior results in a fraction of the time. Completely automated and without manual intervention - this is what EVOBEND stands for.

By upgrading to modern, fully electric technology, you are also making a valuable contribution to sustainability.

We focus on a production process deeply rooted in Germany. With our headquarters in the Berchtesgadener Land and close collaboration with primarily regional partners, we ensure short supply chains and efficient manufacturing. This not only strengthens the local economy but also allows us to deliver high-quality, durable, and reliable products.