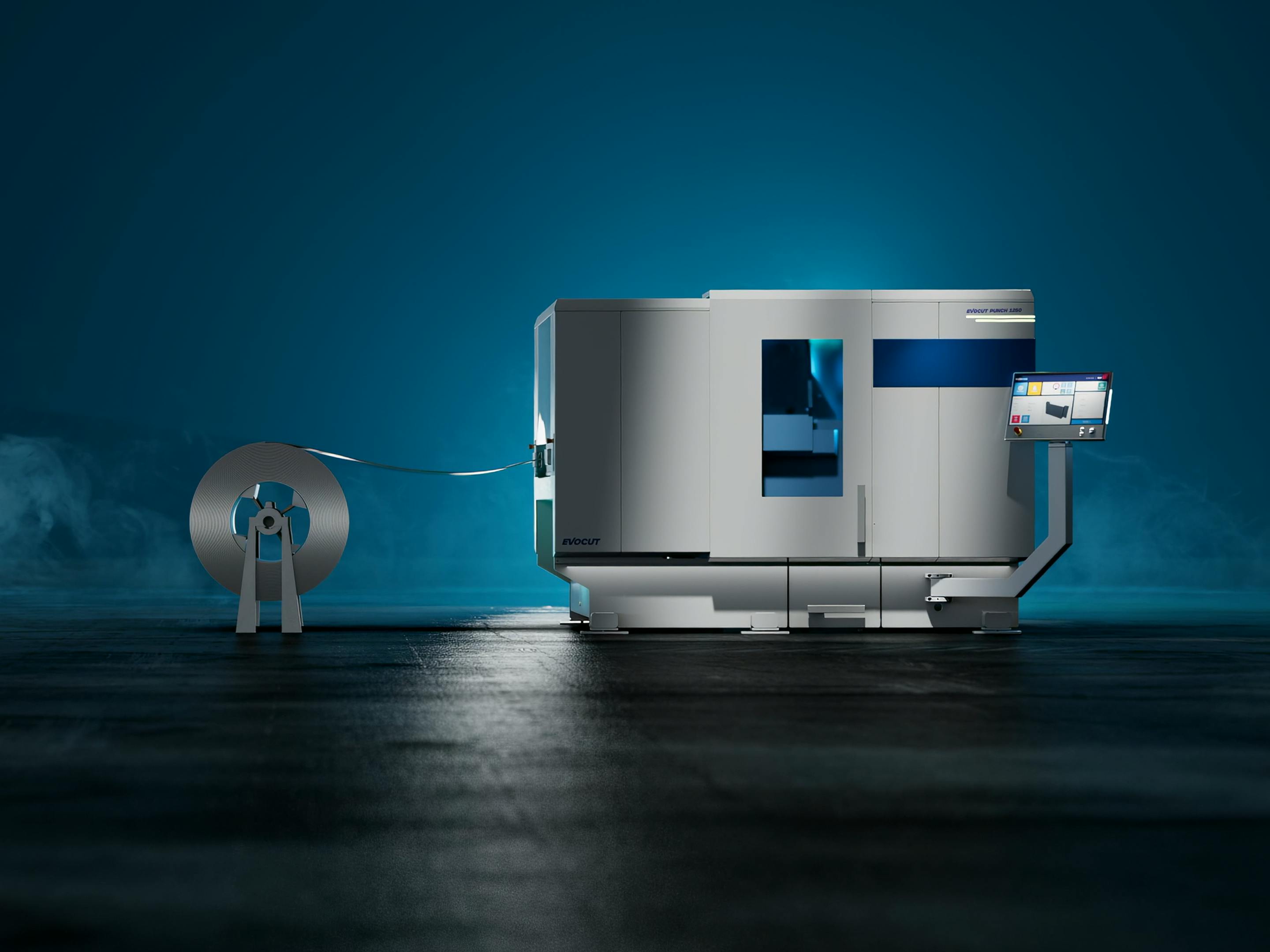

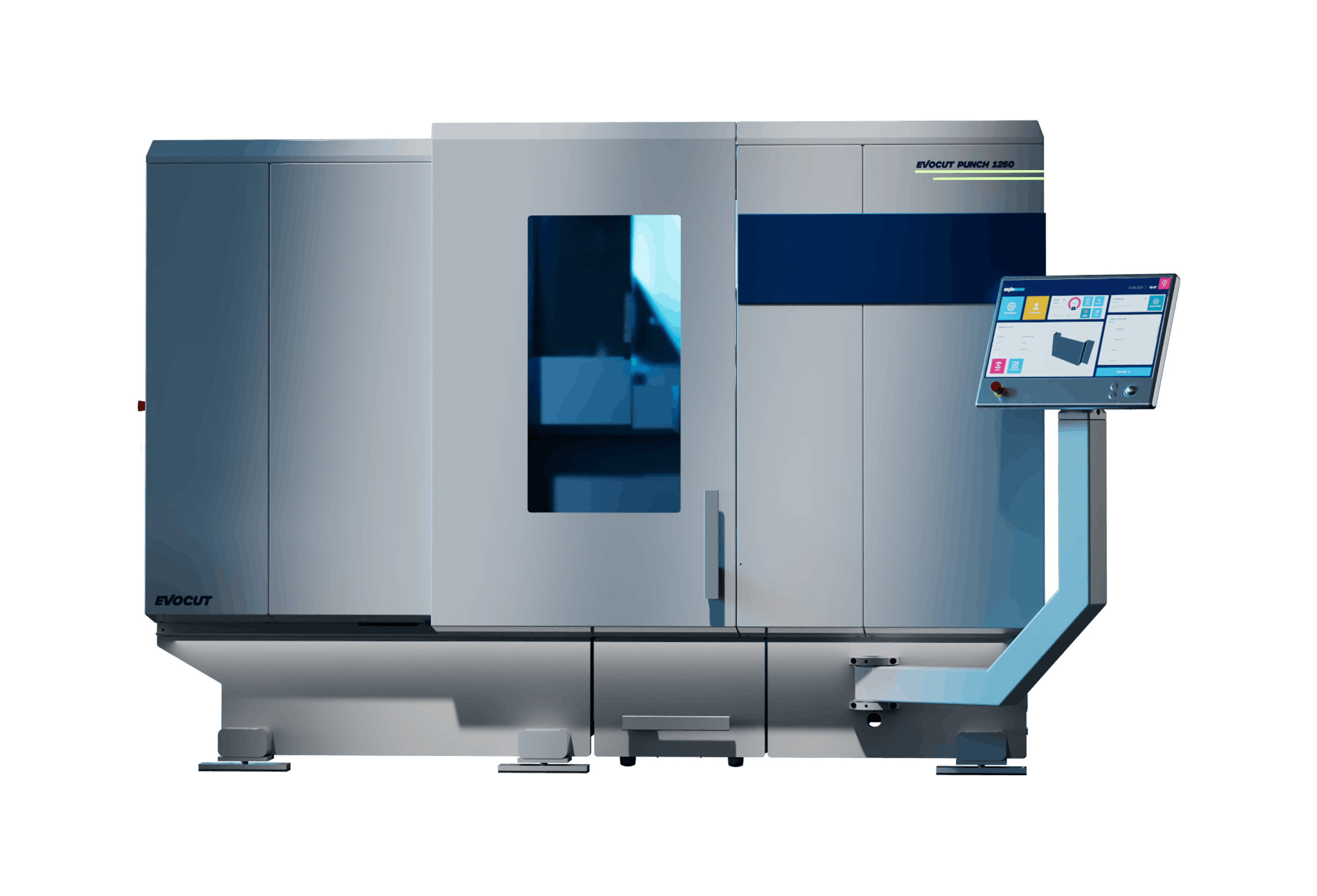

Align

The machine pulls off the sheet metal directly from a coil and automatically aligns it. Various protective films can be applied directly as the sheet enters the machine, to ensure gentle handling and processing of the material.

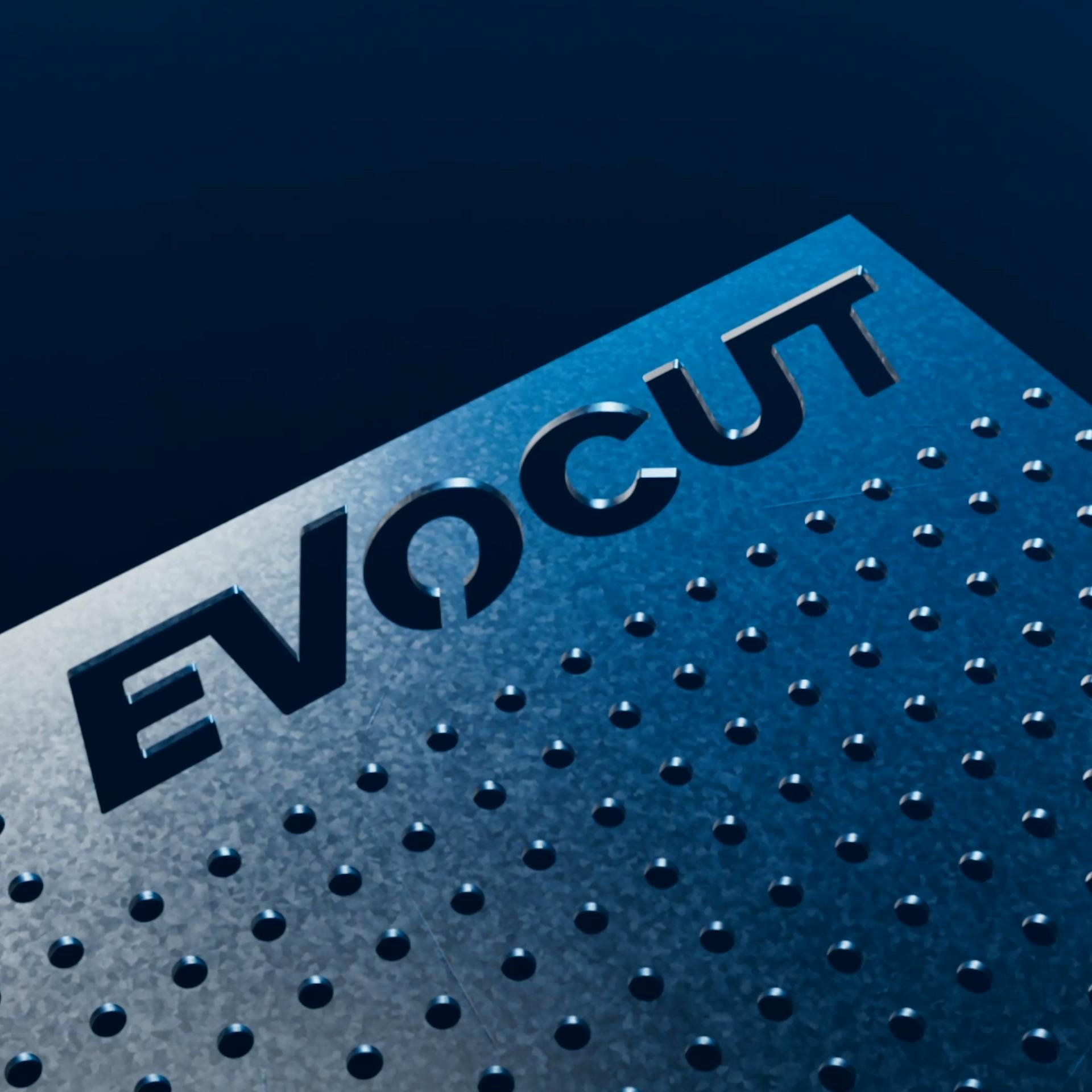

Punch

The EVOCUT punching function allows cutting of any radii, diagonal cuts, as well as custom notches or hole patterns in the sheet metal, without limitations of the sheet width.

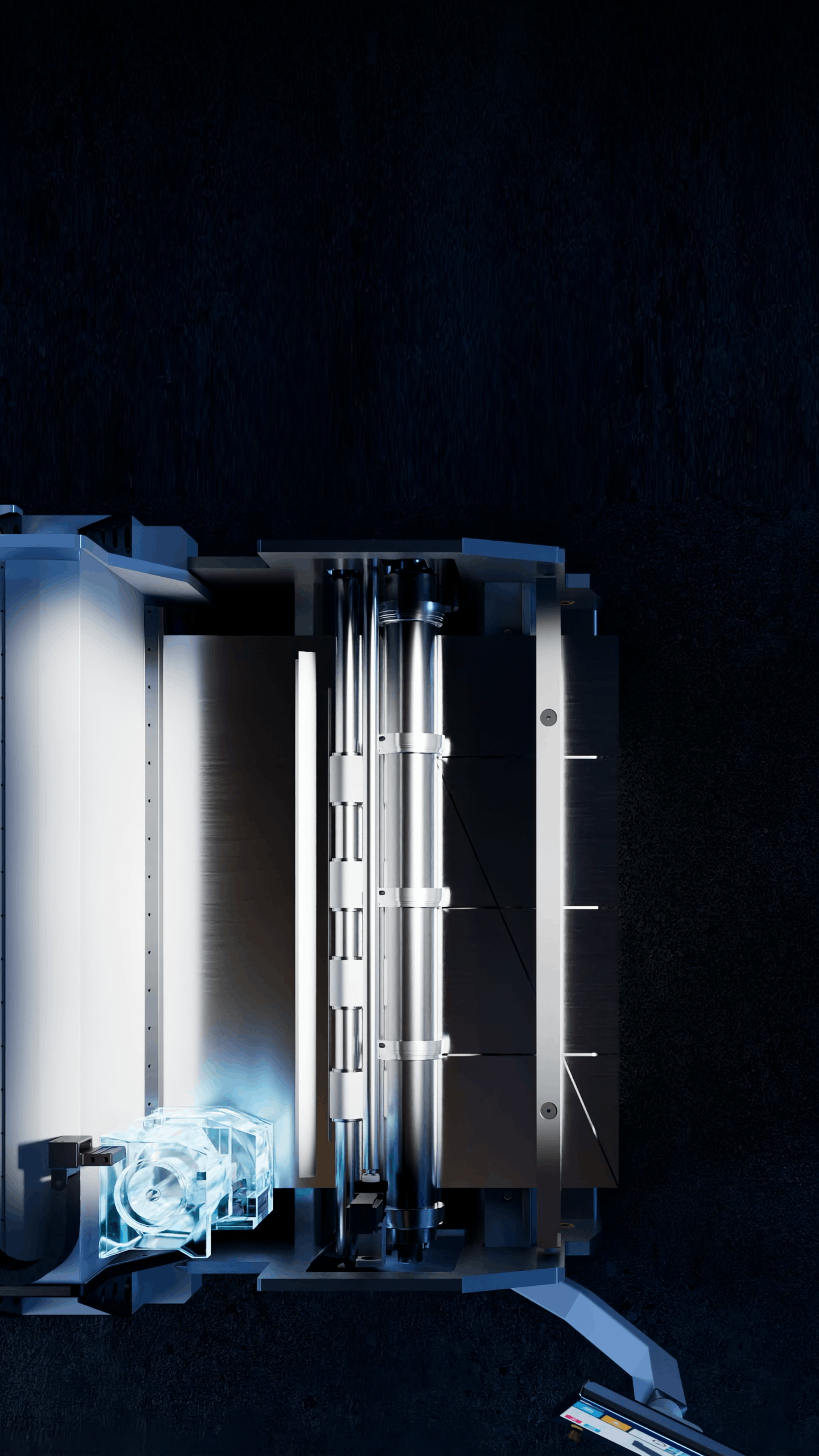

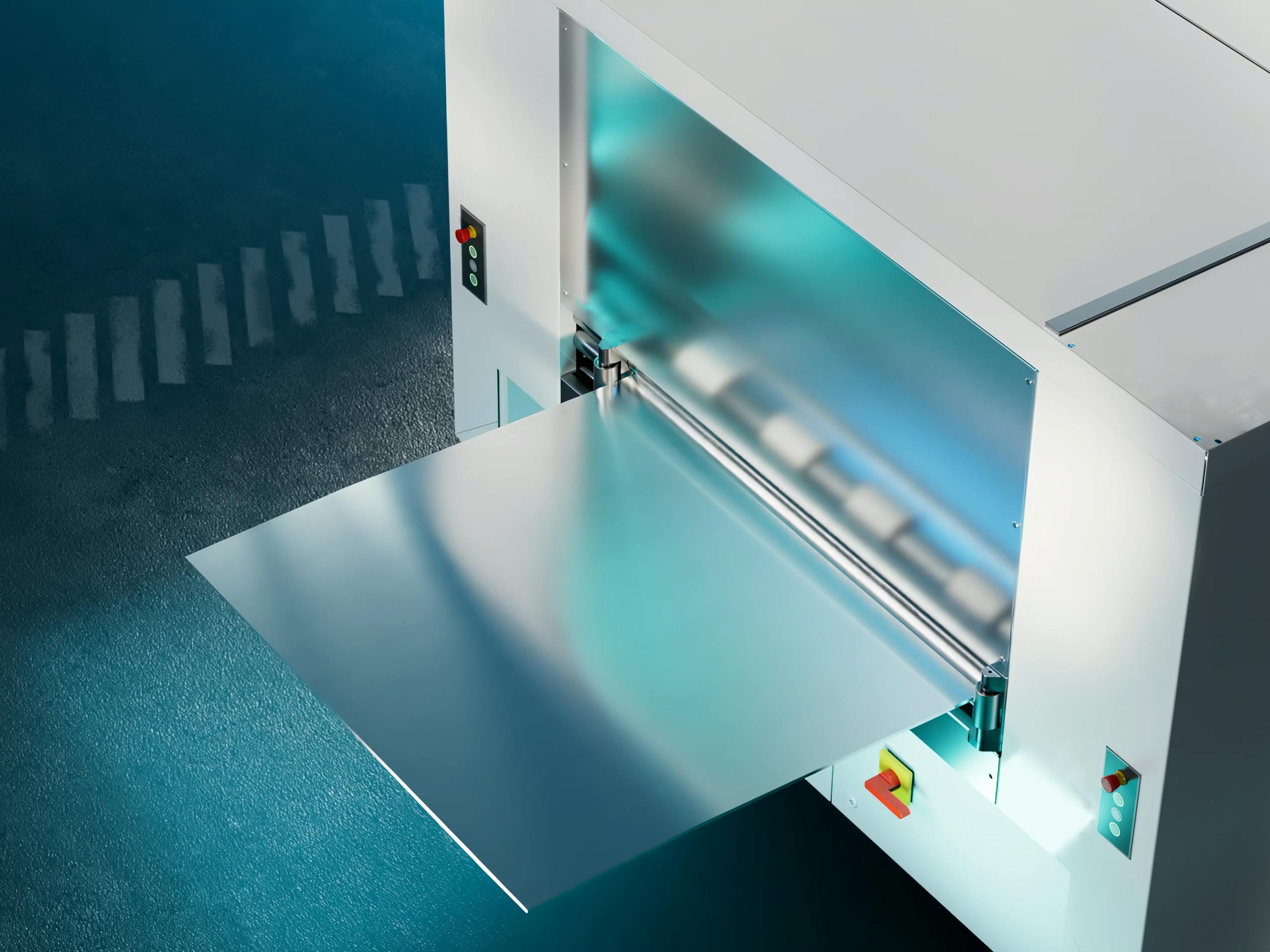

Cut

The EVOCUT enables precise and customized and also partial cutting in both length and width. The automatic adjustment of the knives saves time and is designed for maximum stability and the highest precision.

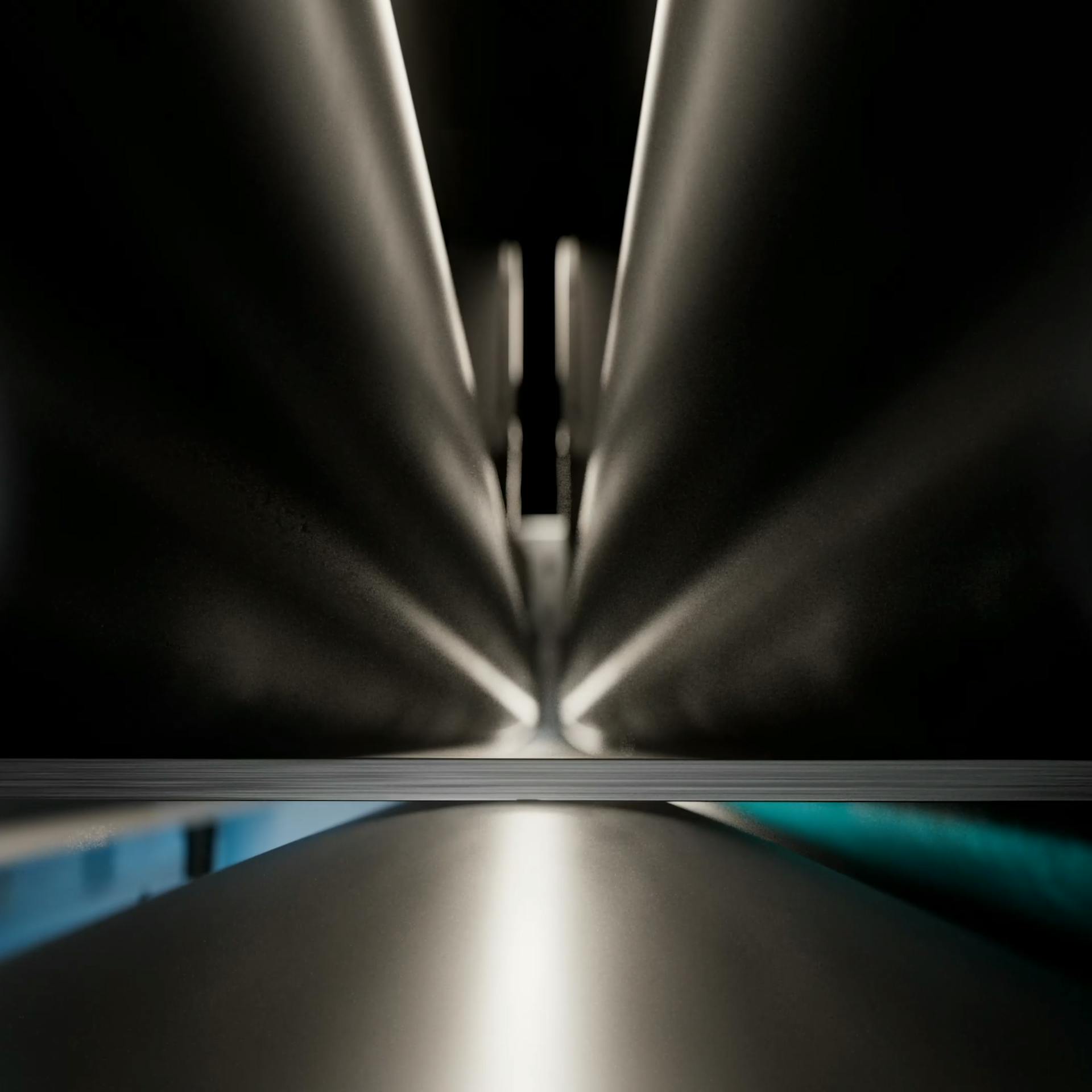

Align

The machine pulls off the sheet metal directly from a coil and automatically aligns it. Various protective films can be applied directly as the sheet enters the machine, to ensure gentle handling and processing of the material.